Mitigating Supply Chain Disruptions for Construction Companies

In recent years, construction companies have faced numerous challenges due to disruptions in the supply chain. These disruptions cause project delays, increased costs, and frustrated clients and can stem from various sources including natural disasters, political instability, transportation issues, or unexpected demand spikes. Each of these factors can cause delays in the delivery of materials, increase costs, and reduce overall efficiency. With careful planning and effective systems in place, construction companies can position themselves for success in unpredictable markets.

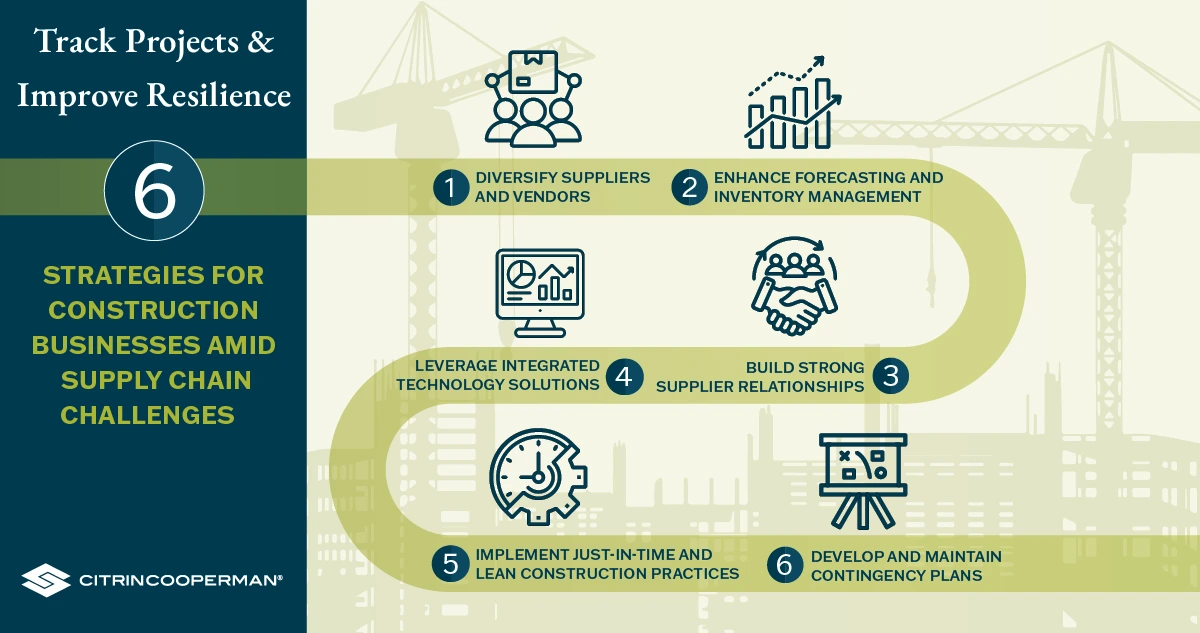

- Diversify Suppliers and Vendors: Avoid reliance on a single supplier by sourcing key materials from multiple vendors across various regions. This reduces vulnerability to disruptions and provides flexibility if supply shocks or delays occur due to geopolitical events, local shortages, or transportation issues.

- Enhance Forecasting and Inventory Management: Utilize data-driven demand forecasting and strategic inventory planning to anticipate future needs and minimize stockouts. Technologies such as predictive analytics and automated inventory systems enable contractors to optimize material flow, proactively order critical items, and create buffer stocks when needed.

- Build Strong Supplier Relationships: Collaborate actively and communicate regularly with suppliers to ensure transparency, reliability, and priority service during shortages or disruptions. Establish long-term contracts where possible, review supplier performance, and maintain backup vendors to prepare for emergencies.

- Leverage Integrated Technology Solutions: Adopt advanced supply chain management tools and digital platforms that provide real-time visibility into inventory, delivery schedules, procurement, and project coordination. Technology-enabled traceability and centralized project data improve responsiveness and help contractors adapt quickly to changing conditions.

- Implement Just-in-Time and Lean Construction Practices: By using lean and just-in-time inventory models, contractors can reduce waste, save on storage costs, and maintain efficiency. This approach ensures materials arrive as needed — streamlining delivery and reducing the risk of obsolete stock during delays or design changes.

- Develop and Maintain Contingency Plans: Map out the entire supply chain, assess risks, and develop contingency plans for potential bottlenecks or disruptions such as natural disasters or market volatility. Scenario planning, risk mitigation protocols, and alternative sourcing strategies can help businesses respond swiftly when challenges arise.

How Citrin Cooperman Can Help

When integrated into strategic planning, these six strategies help contractors manage volatility and keep projects on track to preserve and create value. Citrin Cooperman’s Construction Industry Practice, complemented by our Digital and Cloud Services Practice, helps construction businesses improve operational efficiencies and remain profitable amid ongoing supply chain challenges. For more information, please reach out to Scott Derco.

Latest Article Cards

Strengthening Grantmaking Through Comprehensive Due Diligence

Read More

Building ERP Dashboards That Drive Growth, Not Just Reporting

Read More

AI Strategies Driving Real Business Impact in 2026

Read More

Connected Financial and Sustainability Reporting with Workiva

Read More